For the last several posts, we've given you and your team the science behind our coatings - to equip you better to make the best product choice for the job at hand, or justify costs to customers when demanding a project. Knowledge is power - and in the concrete coating industry, it can make the contrast between choosing a product that saves you time and cash... or adds more labor and maintenance.

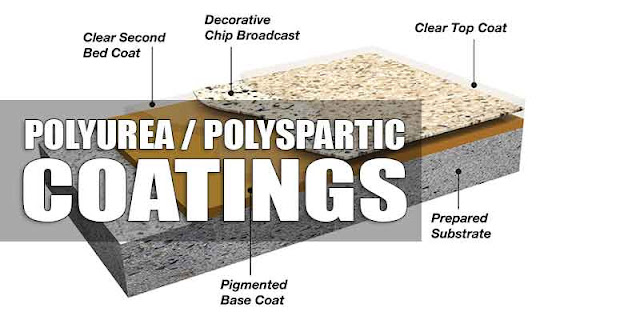

We've covered what polyurea is, the difference between aromatic and aliphatic polyureas and when to use each, and what single-component, as well as 100-solids polyurea are and how they save you time and labor on an install. In this, our fifth and final article in the series, we wanted to put all this information into context:

How does polyurea "measure up" against other similar coatings?

One of our sales team managers, John N., put it this way: "Our product installs differently. Less coats, less labor. Our installers get it."

In other words, once you "go" polyurea, there may be no going back to less versatile, less resilient materials, despite the superficial difference in cost. (Polyureas tend to be more pricey than other products on the market, but that cost is often offset by time, labor and related downtime costs saved, versus other polymer based coatings.)

Here are the key differences between polyurea, epoxy and polyurethane:

Less Installation and Cure Time. As John alluded to, polyurea takes dramatically less time not only to apply, but to cure, with "walk-on" capabilities within hours, and full cure within a day. Add that and 80- or 100-solids polyurea takes fewer coats to achieve the desired level of thickness, and your team can be done and on to the next project - and your customer, back up and running - in a fraction of the time of a comparable coating.

Wider Range of Installation Temperatures. One mistake that some customers have is that concrete coating jobs are a summertime project - which is true for epoxy coatings that require temperatures above 50F. As we head into the winter months, for many of us this temperature range will be a happy memory until spring for outdoor projects. With a variety of installation heats from 30F below to well over 100F, your customer doesn't need to worry about picking the best time of year, and you, the installer, about a temperature-controlled environment or seasonal limits.

Greater Resilience and Maintenance-Free Longevity. Both polyurea and epoxy bond firmly to concrete, where polyurethane's bond is weak - requiring a recoat every 4-7 years. (Both polyurethane and polyurea share versatility, but polyurea won't need to be replaced every few years). Although epoxy's bond is also powerful, it's susceptible to hot tire pick up - making it less useful for use around vehicles, nixing hangars and garage floors, as well as other typical commercial and industrial applications. Epoxy needs some upkeep, where polyurea is maintenance-free. When discussing costs with your customer, you'll want to point out not only the cost of materials and installation, but ongoing maintenance costs... which for polyurea is a very attractive zero.

Lower VOCs for Better Air Quality. In today's age of environmental awareness - and more and more customers vying to be "green" - less VOCs (volatile organic compounds) to smell and breathe as your team works is no small consideration. Polyurea has the lowest VOCs in comparison to polyurethane and epoxy, and no odor when curing.

Better Durability: Chemical and UV Resistance. Both polyurea and polyurethane have high resistance to oil. Polyurea is also chemical- and scratch-resistant. Both polyurethane and polyurea can be used in exterior applications, where UV exposure is an issue - but polyurea is better than polyurethane at UV protection. (UV rays will ultimately yellow or degrade a less resistant coating).

Ease of Use and Good Looking, Too. Polyurea can do what epoxies can in terms of workability and ease of use, as well as color, decorative additives and the like - but without epoxy's long application and cure times and installation restrictions.

Polyurea isn't perpetually the slam-dunk, no-brainer choice, notwithstanding its benefits over epoxy and polyurethane; each project has unique specifications and budget to reflect. To learn whether polyurea is the best fit for your concrete flooring project, click here to schedule a no-obligation consultation with one of our experts.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.